Green and efficient processing technology of functional rapeseed oil 7D producing area

Category: Products

Product Details

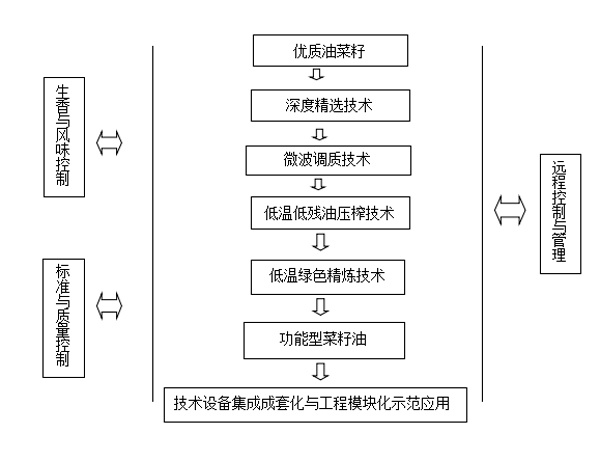

1. Functional Rapeseed Oil 7D Process Technology Roadmap

2. Functional Rapeseed Oil 7D Technology

1 Deep Selection Technology

Based on the difference of physical and chemical properties such as shape, size and density of raw materials, it integrates functions such as screening, winnows, magnetic separation, stone removal and dust removal to efficiently separate non-rapeseed impurities, and the impurity content of rapeseed after selection is less than 0.1%.

2 Microwave upgrading technology

Coupling microwave physical field and hot air heat and mass transfer, energy consumption is reduced by more than 20%, and high-efficiency conditioning of rapeseed, cell micro-expansion, passivation of endogenous enzymes and high-efficiency generation of high-function active rapeseed polyphenol canolol are realized.

3 Low temperature and low residual oil pressing technology

The low-temperature and low-residual oil press, which integrates shearing cone ring, automatic oil residue cleaning and re-squeezing mechanism, realizes automatic low-temperature and high-efficiency squeezing of rapeseed, with the squeezing temperature <90 ℃ and the residual oil of rapeseed cake <7.5%.

4 Low temperature green refining technology

Based on selective physical adsorption of phospholipids, free fatty acids and other impurities, pneumatic automatic feeding and enhanced stirring are integrated to achieve one-step low-temperature physical moderate refining at a refining temperature of less than 45 ℃.

5 Incense and flavor technology

Based on microwave aroma, promote the Maillard reaction, produce roasted nuts aroma and other pleasant flavor, avoid spicy green flavor, make the flavor pure and rich, and the whole process of low temperature physical realization of quality and fragrance.

6 Standards and quality control techniques

Based on the quality standards and production technical specifications of functional rapeseed oil, combined with digital remote transmission, wireless transmission and Internet cloud technology, APP remote product quality and standardized management are realized.

7 Remote technology and management technology

Based on the principle of distributed system control, it integrates three-layer network architecture of sensors, PLC workstations, central server control system and Internet of Things perception system to realize real-time comprehensive perception and monitoring of production.

3. functional rapeseed oil 7D technology is light, green, low consumption and high efficiency

1. Light and simple: the process is reduced by more than 50% compared with salad oil, occupying less land and saving investment;

2. Green: physical pressing, refining, no chemical addition, no waste discharge;

3. Low consumption: energy consumption is reduced by more than 20% and cost is reduced by more than 30%;

4. High efficiency: high product yield, automation, modularization, stable production quality;

4. functional rapeseed oil safety, nutrition, color, flavor and shape

SecurityHealth indicators better than national standards

Health indicators | 7D rapeseed oil | Health indicators GB 2716 |

Arsenic (mg/kg) | Not Checked Out | ≤0.1 |

Lead (mg/kg) | Not Checked Out | ≤0.1 |

Benzo (a) pyrene (µg/kg) | Not Checked Out | ≤10 |

Aflatoxins (µg/kg) | Not Checked Out | ≤10 |

pesticide residue | Not Checked Out | GB 2763 |

Trans fatty acids (%) | Not Checked Out | / |

The quality index is better than the national standard of secondary pressed rapeseed oil

Quality Index | 7D rapeseed oil | GB/T 1536 |

Acid value (mgKOH/g) | ≤1.5 | ≤ 3.0 |

Peroxide value (g/100g) | ≤ 0.12 | ≤ 0.25 |

Moisture and volatile matter (%) | ≤ 0.15 | ≤ 0.15 |

280 ℃ heating test | No precipitate, oil color unchanged | Trace precipitates, darkening of oil color |

Color | Pale yellow to yellow | Orange yellow to tan |

Insoluble impurities (%) | ≤0.05 | ≤0.05 |

Smell, taste | Nut fragrance | The inherent smell and taste of rapeseed oil |

NutritionRich in plant polyphenol Canolol, vitamin E, phytosterol and other active nutrients

Total phenols (mg/kg) | Canolol (mg/kg) | Total tocopherol (mg/kg) | Total Sterols (mg/kg) | Beta-carotene (mg/kg) |

>600 | >800 | >500 | >6000 | >5 |

DeliciousThe flavor is rich and pure, with good baking aroma. The main aromatic substances are dimethyl trisulfide, methyl pyrazine and 2,5-dimethyl -3-ethyl pyrazine, etc.

Key Flavor Components | Odor Description | Content | Threshold | Odor activity value (OAV) |

Dimethyl trisulfide | Nut and cocoa like aroma | 0.18 | 0.0042 | 42.8 |

methyl pyrazine | Baked aroma | 7.3 | 0.2 | 36.4 |

2,5-Dimethyl-3-ethylpyrazine | nut roasted incense | 0.85 | 0.079 | 10.7 |

Health and health effects of 5. functional rapeseed oil

7D rapeseed oil is rich in VE, sterols, Canolol and polyphenols and other active ingredients on dyslipidemia, fatty liver and chronic inflammation and other atherosclerosis risk factors have a positive intervention, conditioning effect.

Advanced nature of 6. technology and equipment

7D technology has won 11 national authorized invention patents, 1 second prize of national science and technology progress, 1 first prize of provincial and ministerial level, 1 Chinese patent excellence award, and 1 scientific and technological innovation promotion achievement award of agricultural products processing industry. In April 2017, it passed the technical evaluation of China Agricultural Association, and the overall technology is in the international leading level.

The company has rich experience in engineering consulting design and industrialization construction of new oil processing technology, which provides strong technical support for creating a diversified utilization situation of China's oil industry and realizing the transformation from single resource advantage to economic advantage and product advantage. Relying on CNPC, the company has developed oil processing equipment and technologies such as double spiral low-temperature oil press, camellia seed shelling machine, rapeseed peeling separation device and high quality rapeseed oil 7D processing technology. The "double screw low-temperature oil press" adopts low-temperature pressing technology, with high working efficiency, low residual oil and wide application range, and won the second prize for scientific and technological progress. The "rapeseed peeling and separation device" adopts a variety of principles to integrate, is fast and efficient, and has a high peeling rate, which can significantly improve the feeding efficiency of cake meal. The shelling rate of the "camellia seed sheller" is as high as high as 95%, the raw material, the raw material without grading, and the separation effect, suitable for shelling a variety of oil seeds with shells; high quality rapeseed oil 7D processing technology integrates "7D" technologies such as deep oil selection (1D), microwave upgrading and aroma generation (2D), low temperature and low residual oil pressing (3D), low temperature green refining (4D), delicious nutrition enhancement (5D), full-process automatic control (6D) and standard and quality management (7D), realizing (1) light process simplification: compared with salad oil, the process is reduced by more than 50%, occupying less land and saving investment. (2) Green production: physical pressing, refining, no chemical addition, no discharge of three wastes;(3) Technical standardization: modularization of production, reduction of energy consumption by more than 20% and cost by more than 30%;(4) Production automation: simple and efficient process, stable quality and high product yield;(5) High value of products: safe and nutritious, rich flavor, pure color, mellow taste, rich in active functional nutrients, for the high quality Chinese good oil.

Keyword:Green and efficient processing technology of functional rapeseed oil 7D producing area

Products

oil

technology

rapeseed

Previous: 7D rapeseed oil

Next: No more

Related Products

flax seed oil xanthophyll ginkgo leaf soft capsule

Rapeseed peeling and kernel separation system

Rapeseed Peel and Peel-kernel Separation System

Camellia seed dehulling machine

Green and efficient processing technology of functional rapeseed oil 7D producing area

Product Inquiry

Leave your phone number and we will contact you within 5 minutes;